How to minimize product damage during transportation

- Choose the Right Packaging Materials

- Optimize Packaging Design for Secure Fit

- Implement Proper Loading and Handling Techniques

- Partner with Reliable Logistics Providers

- In conclusion

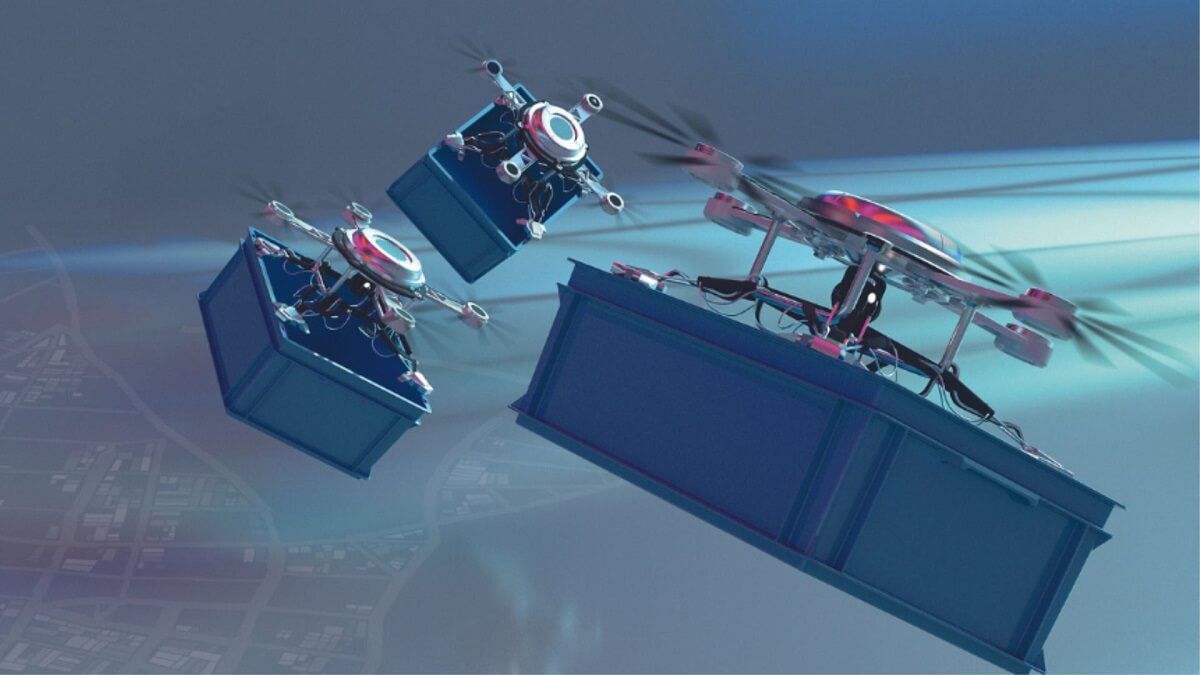

Supply chain efficiency is important to the way any company gets its products to its customers. Custom plastic containers manufacturer options help the shipping process maintain efficiency while protecting products. Forbes says that a poor shipping process can cause businesses to lose customers and raise overall business costs. That’s the last thing any business owner wants. Minimizing product damage while it is being transported is highly important.

Choose the Right Packaging Materials

Selecting the ideal packaging materials for your goods is one method to establish sustainable packaging logistics. When making that decision, keep the following points in mind:

● Durability

Any material you decide to use for packaging must be strong enough to endure any shipping technique you use. To make sure your product won't break when you move it from one location to another, test its durability.

● Aesthetics

It’s important that your product is safe and sound during the transportation process, but you also want it to look good when it gets into the customer’s hands. Make sure the packaging is aesthetically pleasing so it can stand up against your brand’s image.

● Efficiency

Packages need to be efficient so they don’t promote waste. You might consider reusable containers that you invest in once, then don’t have to buy regularly.

● Cost

Any packaging you choose is going to have a cost attached. Check your budget, see what you can afford, then find a packaging option within that range.

Optimize Packaging Design for Secure Fit

Sustainable packaging logistics includes figuring out just the right packaging design for a tight, secure fit. You want your product to fit well in the package without a lot of empty space and waste.

When the product fits the package well, it’s safer, and it cuts down on the need for fillers to protect it against moving around inside the package. All of that leads to efficiency and helps to keep costs as low as possible. You will see less waste and happier customers as well.

Implement Proper Loading and Handling Techniques

The New York Times offers tips on how to save money on shipping and handling. When you have a properly organized loading and handling technique, it can greatly reduce costs and upgrade supply chain efficiency overall. Before allowing warehouse employees to hoist the product around, put a loading and handling process in place.

● Assess

You will need to assess the situation and see what is necessary. How heavy will the packages be? Will there be lots of products in one box, or just one? Make sure there are clear paths to and from the destination, and if the load will be heavy, consider mechanical help.

● Mechanics

When warehouse workers are getting ready to lift heavier products, teach them to lift smoothly without jerky movements so they can avoid muscle strain. Teach them to lift with their legs instead of their backs as well.

● Stability

The products will need to be stable at all times. Warehouse floors need to be dry to avoid slips. Make sure any base, whether it’s a lifter or a place to put the packages, is stable and secure.

● Safety

When it comes to moving objects during transit, safety comes first. As much as you want your products to be safe, your personnel must handle things correctly to protect themselves.

Partner with Reliable Logistics Providers

Packaging cost savings can only go so far if you don’t have a reliable logistics provider to help you with transportation. These suppliers present chances for cost savings that lessen supply chain interruptions. When selecting a logistics partner, keep the following points in mind.

● Track Record

Word of mouth is huge in any industry, and logistics is no different. Check the business’s customer testimonials, reputation, and references to see what others say about their experiences with their services.

● Flexibility

Choose a business partner that is able to give you the flexibility you need, whether it’s due to your demand, events, seasons, or something else you may face.

● Scale

You may own a small business now, but you plan to grow. You need a logistics coordinator who can grow with you to a larger scale, should your needs change.

● Innovation

The right partner should use technology and innovative ideas so you can see real-time supply chain information and play around with digital solutions.

● Costs/Value

You need to keep your budget on track, and the right logistics partner can give you value with the coordination, actually saving you money in the long run.

● Reliability

This is an area you can’t go without, and you need on-time deliveries without interruptions. Reliability is of utmost importance.

In conclusion

No business owner wants products to be damaged during transportation, but with the right packaging and logistics, damage can be kept to a minimum. Utz Group is here to help you create that packaging and then get your products where they need to go.